Laminated Safety Glass for Railways

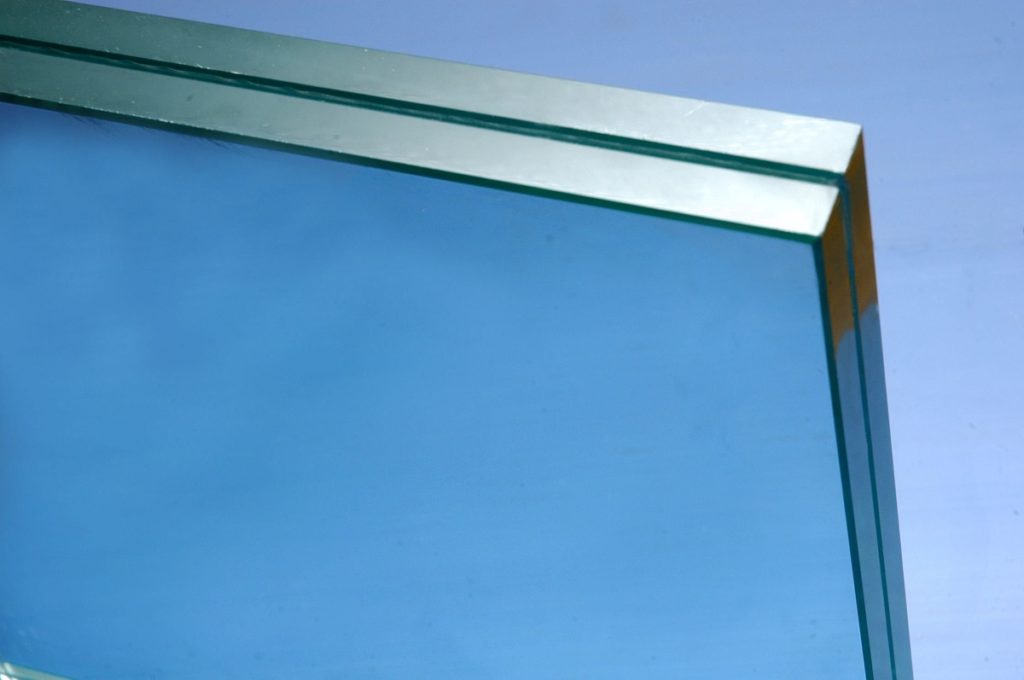

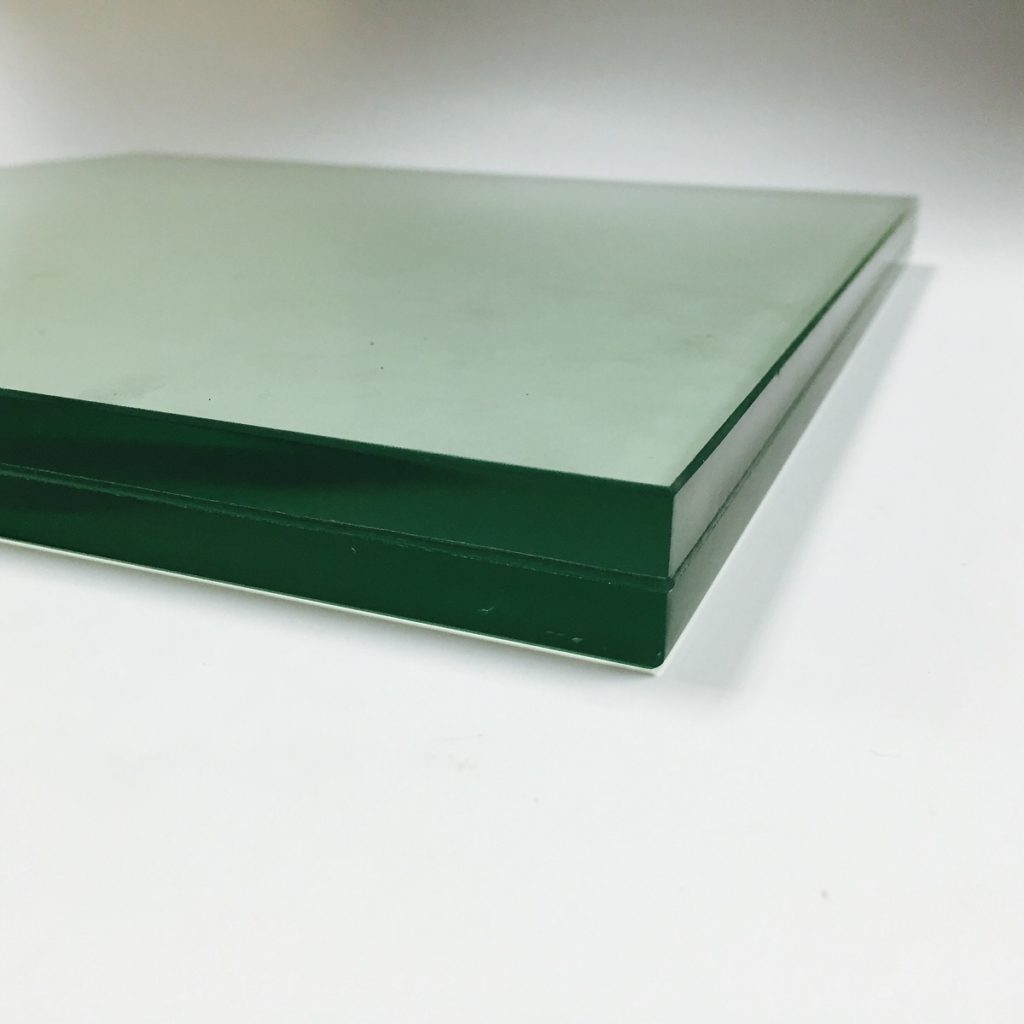

Laminated glass is a kind of safety glass that clamps together when damaged. In case of breaking, it is held and set up by an interlayer, normally of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA), between its two or more layers of glass.

The interlayer keeps the layers of glass fortified even when broken, and its high quality keeps the glass from separating into huge sharp pieces. This creates a trademark "spider web" breaking pattern when the effect isn't sufficient to totally break the glass. In the case of the EVA, the thermoset EVA offers a total bounding (cross-linking) with the material whether it is glass, polycarbonate, PET, or different sorts of items.

Laminated Glass Process:

Laminated glass is made by blending at least two toughened or warmth treated glass sheets fortified with at least one of PVB interlayers and subjected to heat and pressure, in order to ensure ideal attachment between the constituent components.

Glass Pre-Processing:

- Cutting and grinding the material

- Washing it properly

- Drying it completely

- Doing Lamination

- De-airing/edge sealing

- Unloading

Features of Laminated Glass:

Laminated glass gives durability, high-performance, and multi-functional advantages and simultaneously protects the tasteful appearance of glass. Laminated glass gives an answer for some structural plan issues and offers expanded protection from the impacts of debacles, for example, hurricane, earthquake and bomb blasts, if reasonably planned.

Laminated Safety Glass attempts to guarantee customer fulfillment at each level. When you place an order as your rail vehicle glass manufacturers, our adaptable, proficient and friendly team is available to address questions you may have regarding the assembling or conveyance process.